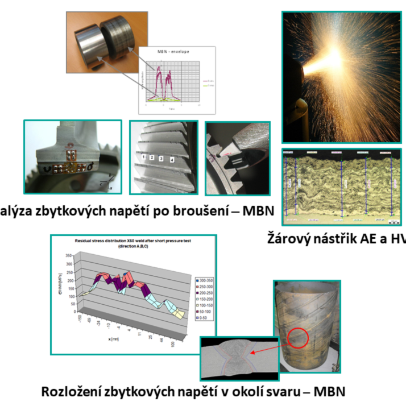

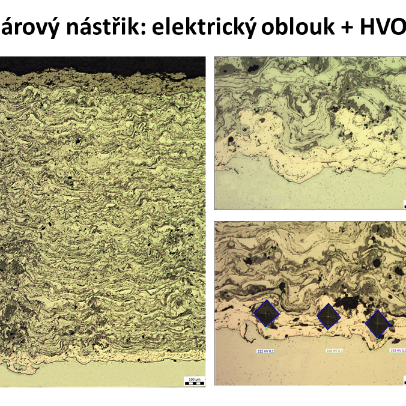

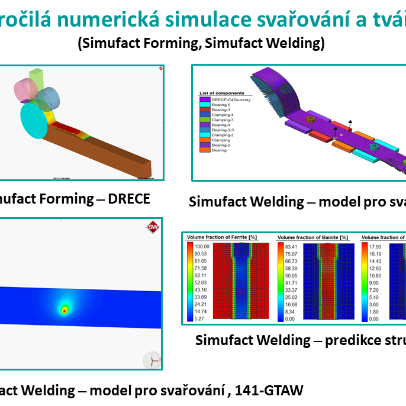

Welding Monitoring and Modelling Laboratory (L122 and N112): Used to monitor fusion and pressure welding technologies. The welding parameters, temperature, and voltage fields are monitored during the welding process. The laboratory prepares material and process data for advanced numerical simulation of the welding and heat treatment process. There is a universal control panel OMB – DAQ – 56 (16 measuring points) and a fast control panel for 8 measuring points. The magnetoelastic method (Meb2c and Intromat equipment) is used mainly for the analysis of residual stresses. The laboratory also has a welding simulator FRONIUS, which is used to teach students and address interested students during university events.